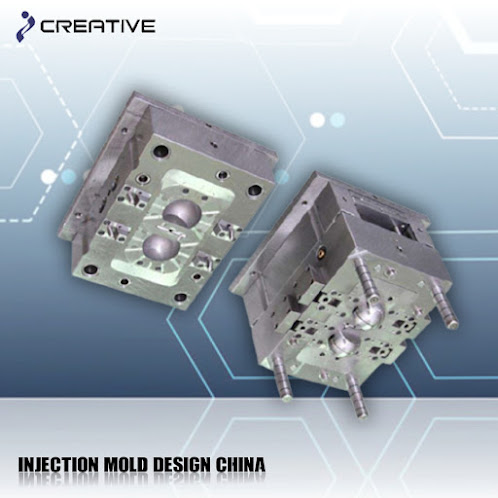

Get Customized Plastic Mold Maker in China

Plastic injection molding is the preferred technique for making plastic products. Injection molding is used to create a wide range of items, including the bulk of plastic goods currently available on the market, containers, bottle caps, automobile interiors, and electronic housings. Multi-cavity injection molds are ideal for making large quantities of plastic components since they can generate many parts in each cycle. Injection molding has a number of advantages, which is why Plastic Mold Maker use it. These advantages include high tolerance precision, repeatability, a large range of material alternatives, cheap labour costs, minimum scrap waste, and no requirement for post-mold polishing. At Creative Innovation, we follow stringent protocols to deliver high quality molds to our customers.

Our technology and

expertise

No matter

what plastic items your business needs or wants to make, a plastic mold maker is a great choice to buy molds from. Every mold

we make is custom-made to your specifications, and we can even create molds

that outlive high-volume, high-tolerance production. At Creative Innovation, we perform support

and modification work. This involves managing and maintaining mold-making

equipment, testing molds to make sure they adhere to customer specifications,

altering molds to match those standards, and performing quality control on the

produced goods. In our plant, we have cutting-edge production and support

equipment. Ten high-speed CNC machines from Taiwan and Japan are present. The

highest speed is attainable at 30,000 rpm. And the largest work surface

measures 2500 by 1500mm.

Otherwise, a

4-unit double-head EDM machine with graphite can work on steel with a mirror

finish and has a shorter lead time for production. The largest work surface

measures 2600*1800mm. The molds and injection parts can meet the environmental

standards of European and American nations thanks to the perfect 5S workshop

management system, and more than 80% of our molds and products have been exported

abroad. Choosing a great Plastic Mold Maker China

essentially ensures that you receive a mold as well as support at every stage

of production.

Tools are frequently made of hardened

tool steel or aluminium depending on what you need them for. Aluminium tooling

is typically used when only a few parts are needed, particularly while

prototyping. Despite being more expensive, steel is frequently the more robust

of the two materials. For any further queries regarding this process, feel free

to contact Creative Innovation plastic

mold maker Company

Contact: +86 755-8822 8008

Email: david@ci-corp.com.cn

Comments

Post a Comment