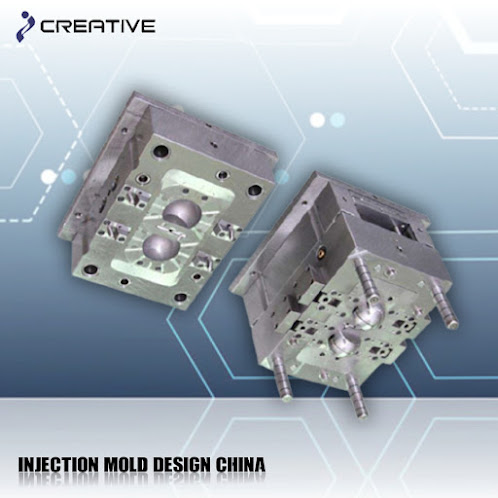

High-Quality Plastic Moulding Company in China

In mass manufacturing processes where the same component is manufactured hundreds or even millions of times, Plastic injection molding, a manufacturing technique for producing several parts at once, is most frequently used. The fundamental advantage of a Plastic injection molding Company is its ability to scale production in huge volumes. The cost per unit for products made by injection molding is quite inexpensive once the initial costs are paid for. The price also tends to drop significantly when more parts are produced. The PlasticMoulding Company does it with the following steps:

Clamping

Before the material is put

into the mold, both halves must be sealed. To close them, a clamping mechanism

is employed. Once the two parts are connected to the injection molding machine

by the Plastic Moulding Company,

one-half may then slide. The pieces are pressed together by the clamping

mechanism, and the material is then injected while both halves are firmly

fastened. For larger, more powerful machines, closing and clamping the mold

takes longer.

Injecting process

Plastic pellets are fed

into the injection molding process using a hopper. These pellets are moved in

the mold's direction by the injection unit. The pressure and heat surrounding

the barrel from the Plastic Moulding

Company melt the pellets. The term "shot" describes the dosage

that is given. After the injection, time is finished or the mold is filled to a

level of 95% to 99%. The dynamic and ever-changing plastic flow makes it

difficult to exactly calculate the insertion duration. It is possible to

forecast injection time using additional factors like injection pressure,

power, and shot volume.

Cooling procedure

The plastic inside the

mold begins to cool after coming into contact with the interior. As it cools,

the plastic will take the desired shape as it hardens. As it cools, the

component might slightly shrink. Only after the cooling period is over can the

injection mold maker open the mold.

Ejecting the mold

Ejection from the machine

is the last step. An ejection system is used for this. Force must be used to

force the item out of the mold as it opens because it shrinks and adheres to

the mold. After ejection, the mold can be closed once more, and another shot

can be injected to start the process over the Plastic Moulding Company.

Comments

Post a Comment